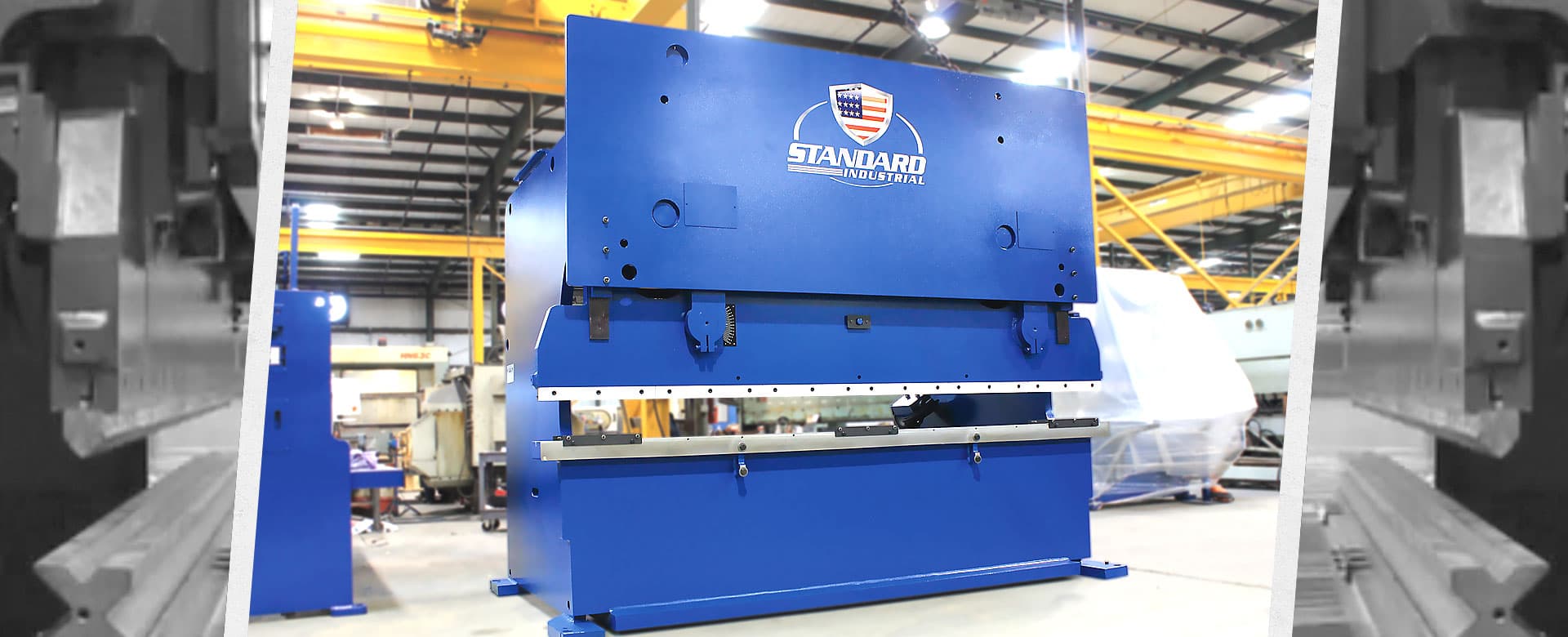

Single Cylinder Press Brake Excell

Sheet Metal

Backed by Standard Industrial's reputation for durability and repeatability, our press brake machines offer important advantages over other models.

The PA Plus series is a powerful combination of functionality and versatility. The PA Plus series can be customized with a wide range of accessories.