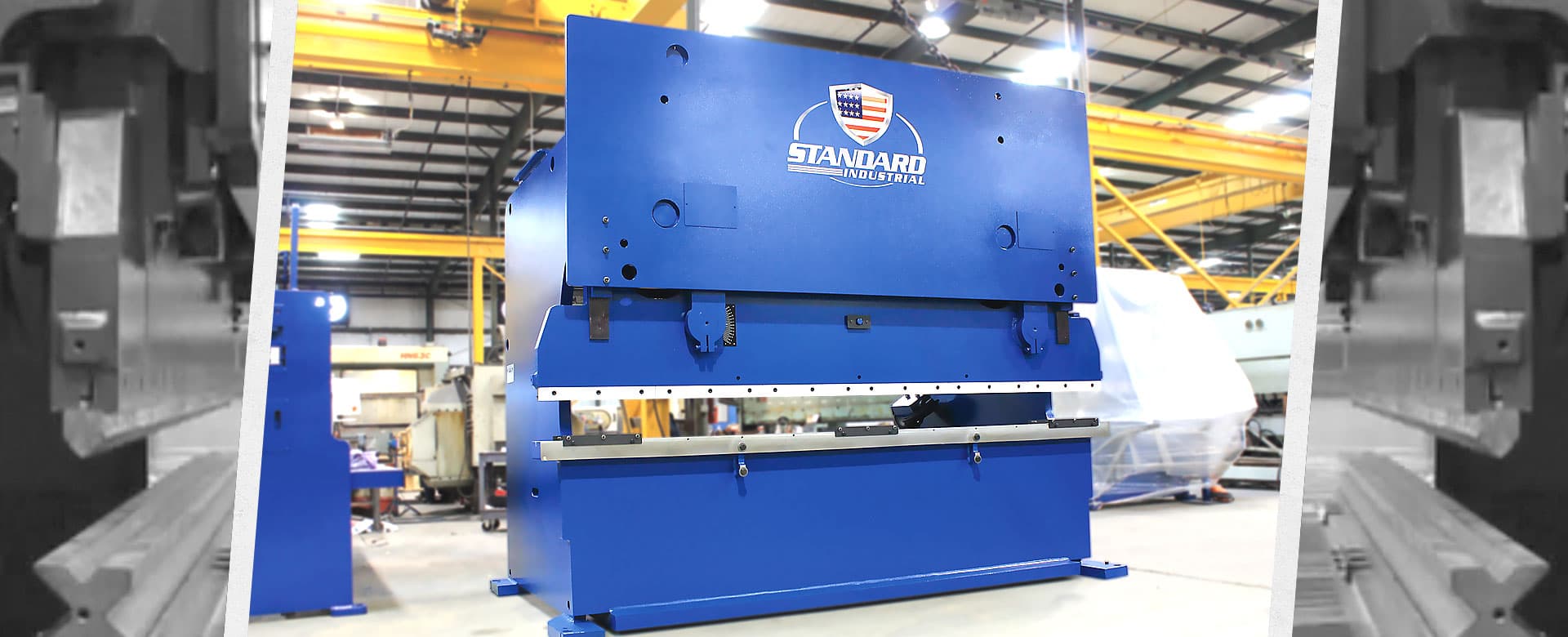

Single Cylinder Press Brake In The World

Milling

This is for realigning dies or off-center loading applications. It takes only seconds to change levels. Our ram level indicator displays the distance from the zero (ram level) point. This indicator is simple to read and clear. Your order can include power tilting systems.

This method gives high precision in angular measurements. This method can be used on sheet metal up to 2 mm thick.