Single Cylinder Press Brake Guarding

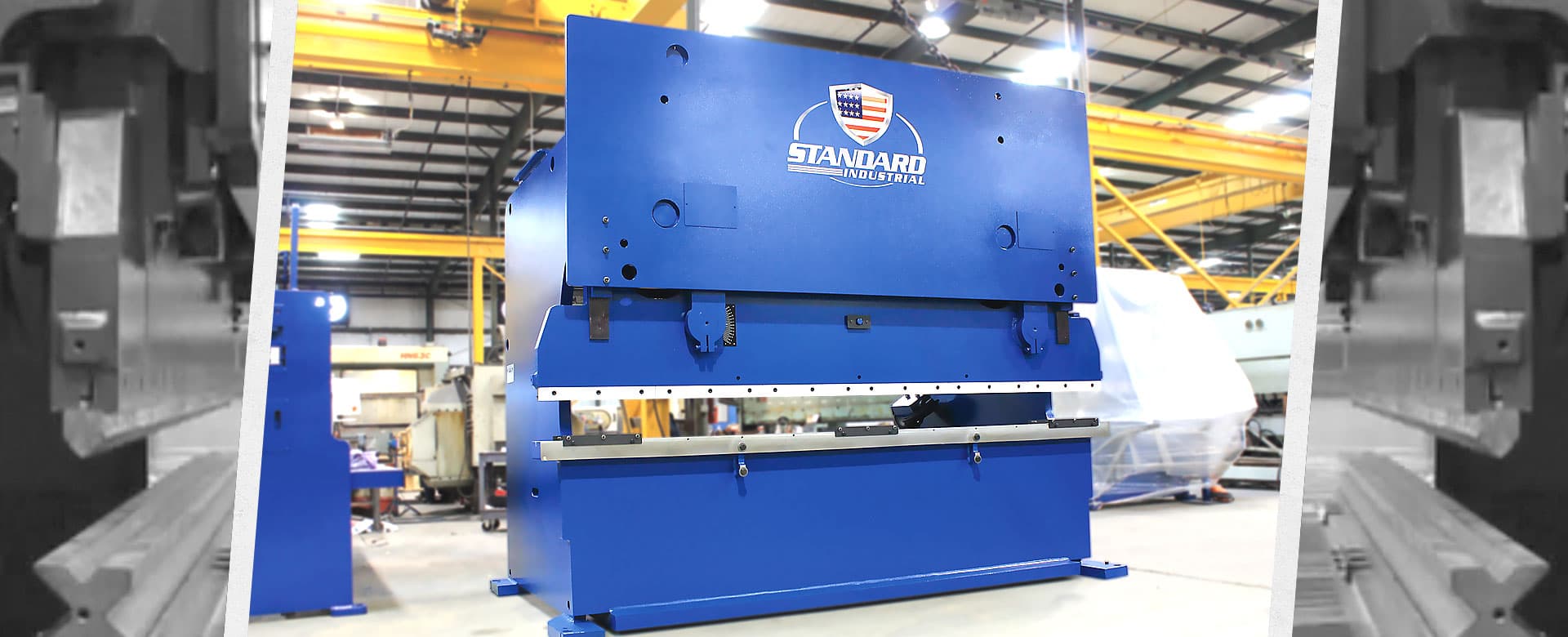

Single Cylinder Press Brake Ex

Standard's warranty includes a limited 5-year warranty for onsite labor as well as a 1-year CNC/PLC Warrant. This warranty also includes unlimited lifetime telephone support without charge.

ADR and ADS hydraulic brakes are just as fast as they can be. These press brakes make it the best machine in the world, with repeatability and accuracy to match. Our JMT line of press brakes has the same concept as all other JMT presses. These machines have large strokes, high openings or deep throats that allow operators to make more complicated parts. You will have more parts in your bin by the end the shift thanks to a faster setup and more operator friendly controls.

Single Cylinder Press Brake Guarding