Single Cylinder Press Brake Back

Single Cylinder Press Brake Laser Line

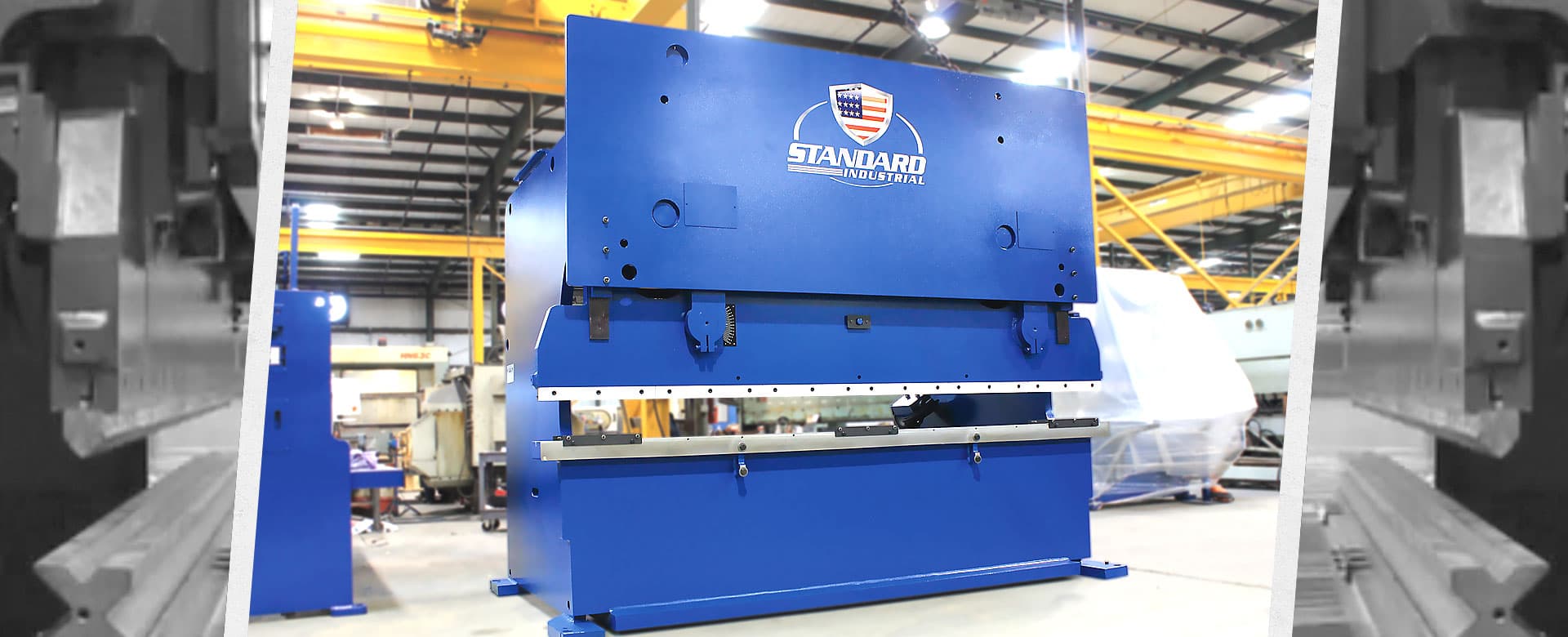

Standard Industrial Press brakes are available for any size facility. This includes the smaller, more cost-conscious facilities that do piece by piece work and the larger production companies that require reliable machines that can be reassembled with minimal downtime.

In air bending, the end of the punch and the 2 edges of the V allow the sheet metal to be bent. But this type of bending means there is a spring back effect of the work piece. As the bending force is weaker, the metal sheet springs backwards like an elastic when the punch is removed.