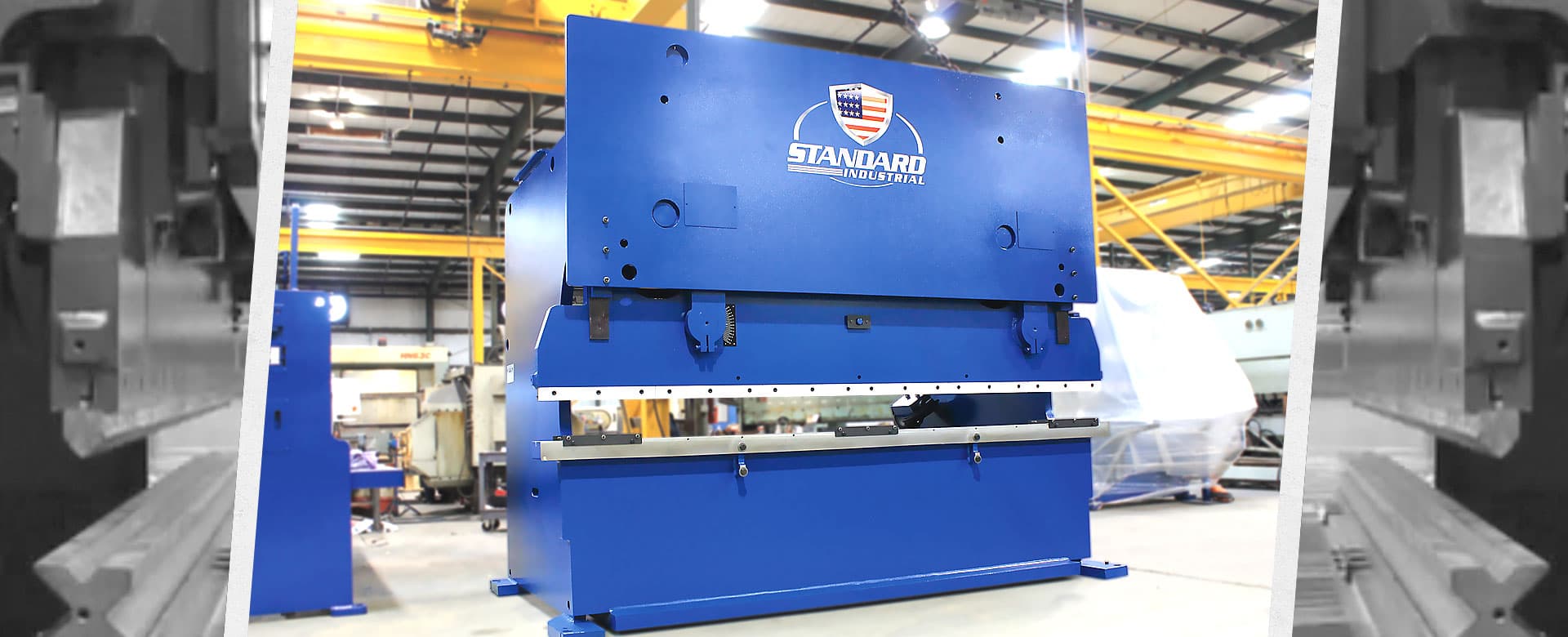

ADR and ADS hydraulic press brakes are as accurate as they are fast. These press brakes are second only to none. They can achieve accuracy levels of +-.0004 with repeatability that matches. These machines are similar to all of the JMT press brakes. They feature large strokes, high openings, and deep throats. This allows the operator to make larger parts and makes it easier to remove those parts. The result is a faster setup, more operator-friendly control, and a press that moves at breakneck speeds. This allows for more parts to be in the bin by shift's end with a higher quality overall piece to piece.

The next step is to determine the characteristics that will be used to calculate the part bend. For example: