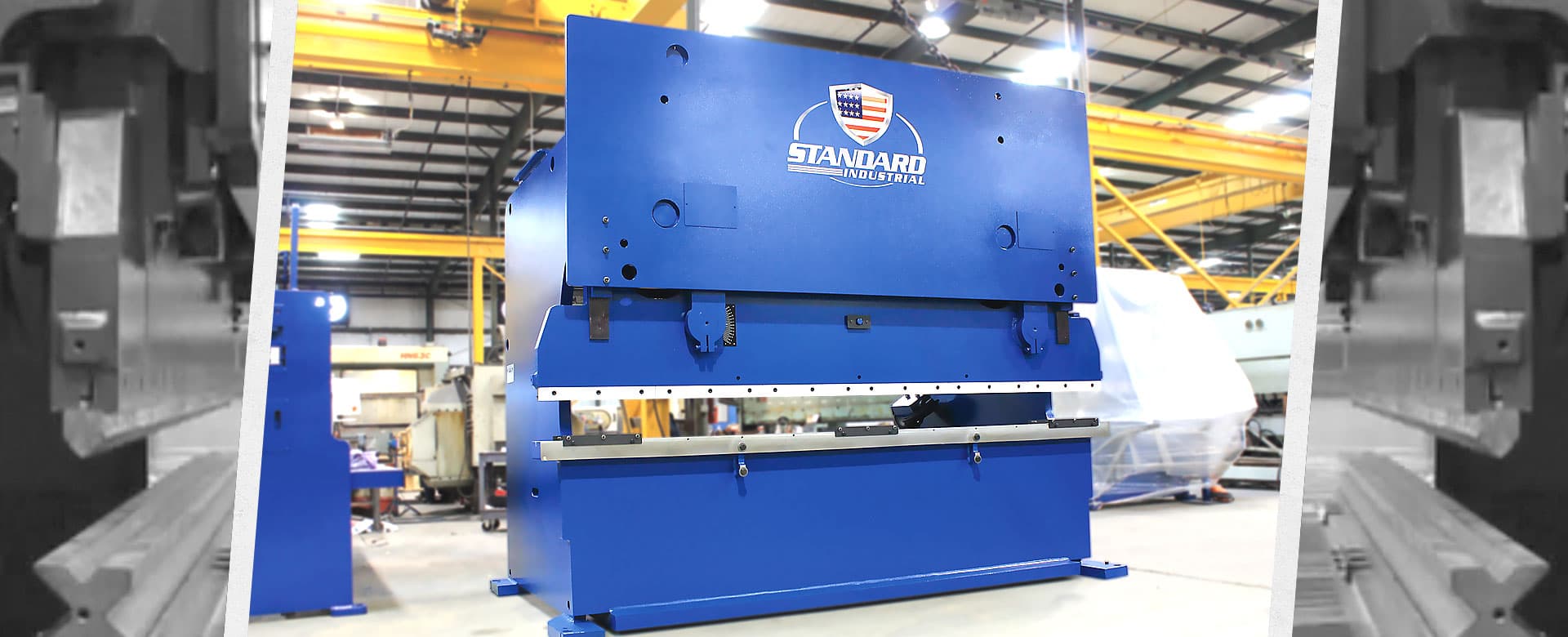

Single Cylinder Press Brake Island

Single Cylinder Press Brake Coast

Standard Industrial Corp. has an extended warranty that increases the 5-year warranty on parts by 2 year. This offer includes the following:

Standard Industrial will provide onsite labor to resolve any remaining issues for the first five-year period, once all other telephone troubleshooting options have been exhausted. The warranty applies to three shifts per 24 hour days and is based on three shifts per working day. A 7 Year Extended Warranty, which extends the warranty by two additional years for all machines, is available.