Single Cylinder Press Brake Calculator

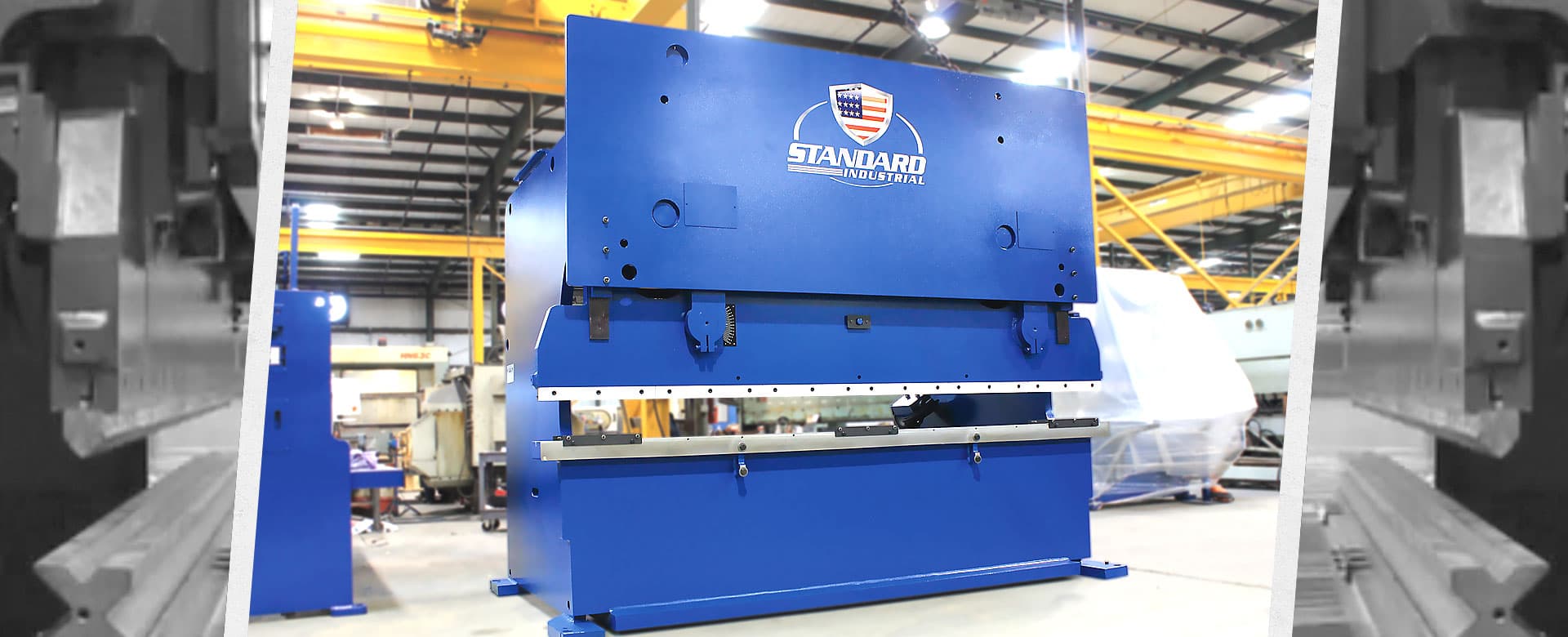

Single Cylinder Press Brake Band

Looking for the ideal combination of serious bending strength and cost-efficient operation without sacrificing quality or output?

We also offer a variety of Press Brakes that are hydraulically controlled. The bending power of the brake is strong enough to handle large work-pieces. Because of its large tonnage, it can handle any thick metal material. This range is available in Single Cylinder and Dual Cylinder Y1+Y2 formats. It requires minimal operation. You can use our Press Brakes to process metals such as steel, brass, metal sheets and aluminum alloys.

Single Cylinder Press Brake Calculator