Single Cylinder Press Brake Bend Radius Chart

Single Cylinder Press Brake Harbor Freight

Gulf States Saw & Machine. Co is a member the American Welding Society.

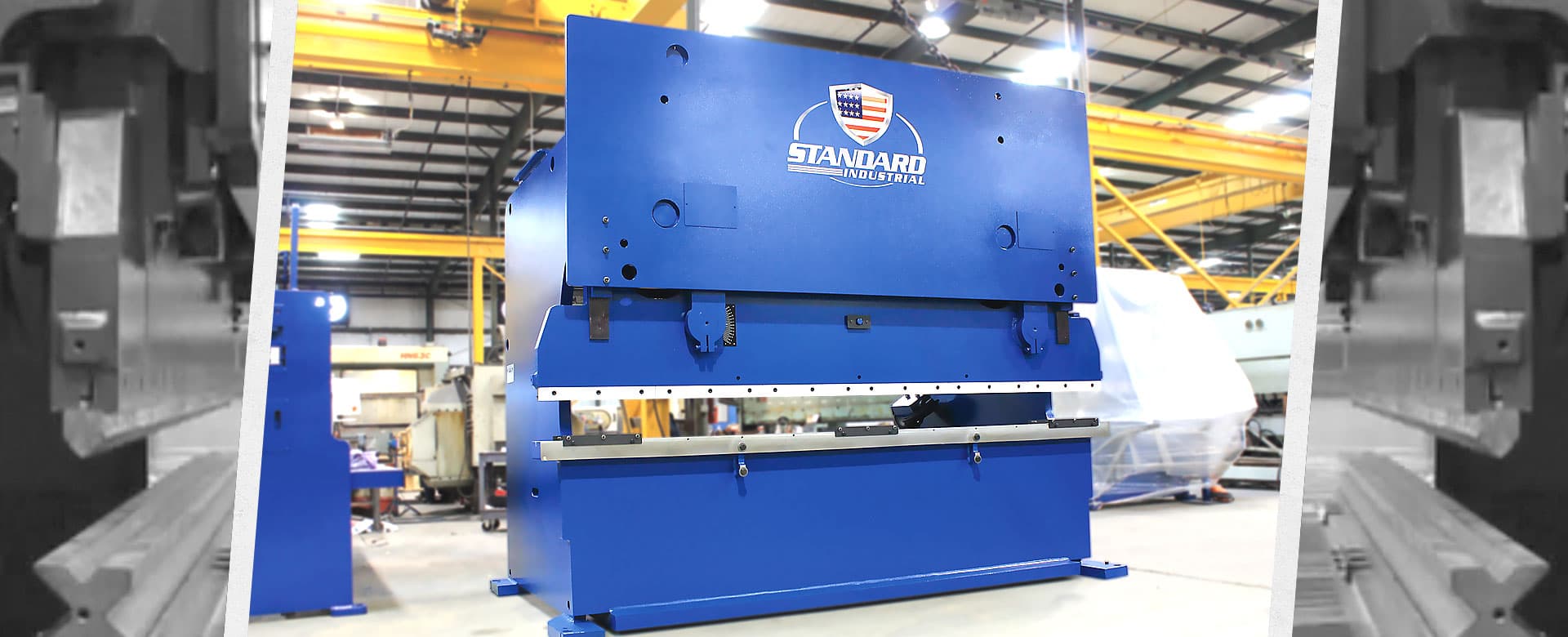

Standard Industrial Corp. offers an extended warranty that extends an existing 5-year parts warrantee by 2 years. This offer includes: