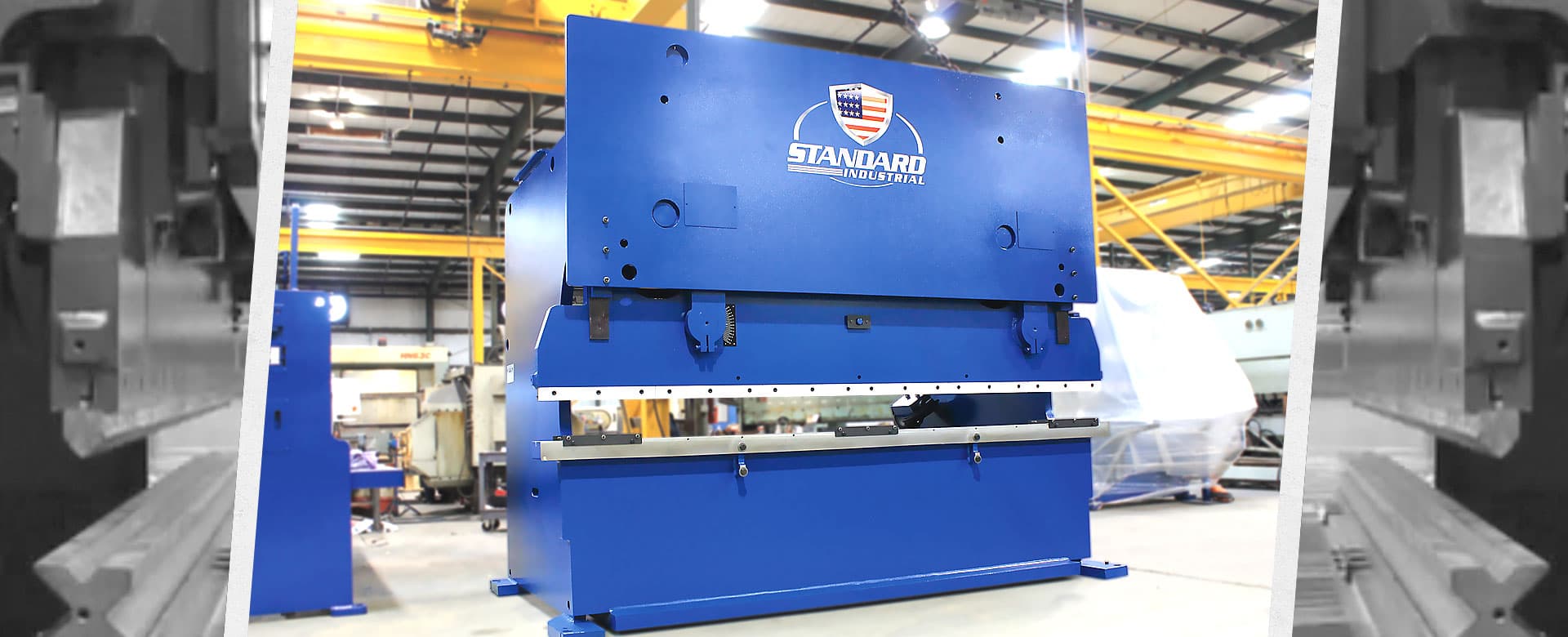

H Frame Press Brake

Single Cylinder Press Brake Hook

High-speed hydraulics packages are available to enhance the productivity of press brakes. To maintain temperature and prolong system life, an oil cooler is installed. Call a representative to learn more about our standard systems or custom-designed systems.

This dual-drive hybrid makes short work of any project with long term, high speed, energy-efficient operation.