Difference Between Press Brake And Pan Brake

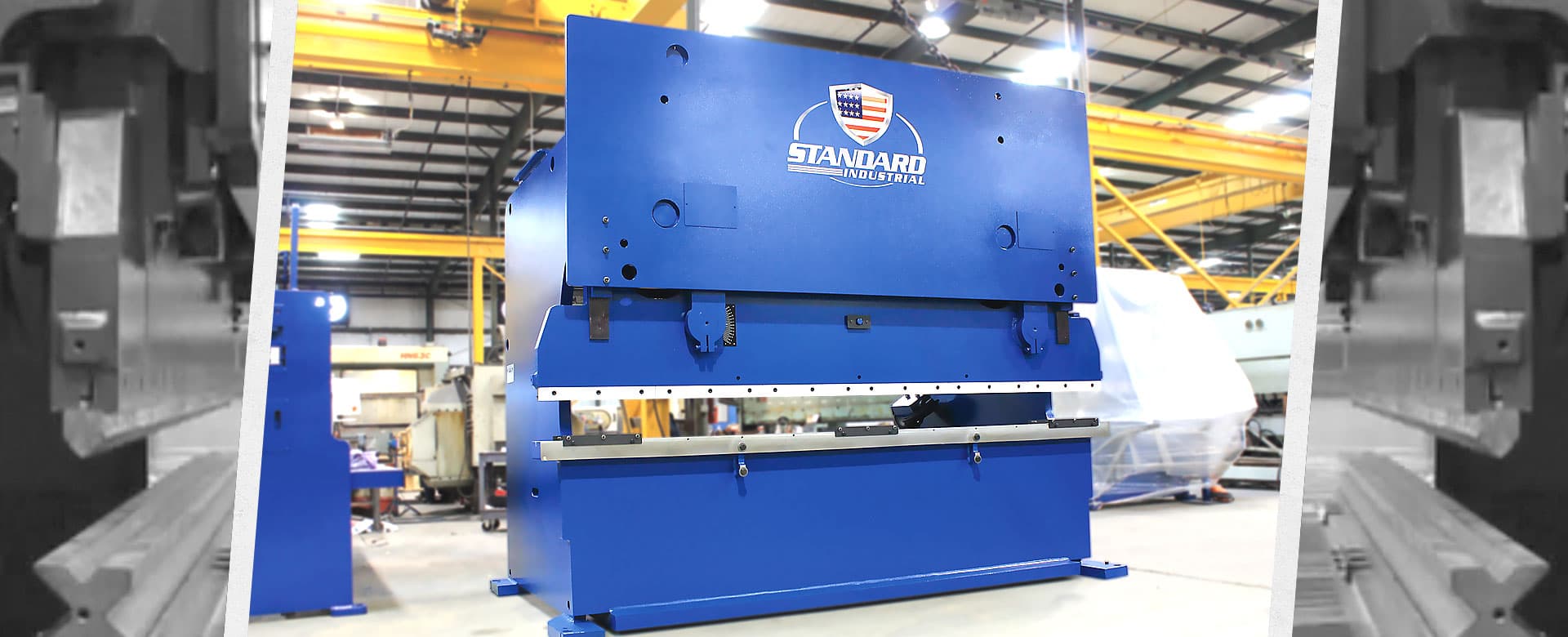

Single Cylinder Press Brake Ic

What is the process of making a Piranha press brake work? Although our current models may be new, we have been making press brakes since 1998. Our customers love our single-cylinder and double-cylinder press brakes. We have also designed and engineered many other great machines. The cost of steel for fabrication in the U.S. was too high. Our customers and dealers kept asking us to make a new press brake after we had stopped producing. They loved our machine and how we cared for them. They liked the convenience of having one place they could go to get repair or purchase parts for all their equipment.

These machines are fast and efficient, as they run faster, more efficiently, and with greater reliability than their predecessors.