Production

To dispense and recover welding flux, a flux recovery system can be used. Seam Welder Hydraulic Power Units and Electric Controls are used to drive conveyors at the Seam Welder's entrance and exit.

.jpg)

There will never be enough H beam welding machinery on the marketplace, especially considering the increase in manufacturers. Gulf States Saw & Machinery Co. can be trusted as the best manufacturer, and we have a long history of satisfied customers.

The wire feeding device can be fixed in an arc-guiding device. It can connect wire feeder to wire reel by using wire feeding pipe. The wire reel supporter is used to fix wire reel. After placing wire reel in the supporter, weld wire thrill through the feeding pipe and connect it with the feeding machine.

To dispense and recover welding flux, a flux recovery system can be used. Seam Welder Hydraulic Power Units and Electric Controls are used to drive conveyors at the Seam Welder's entrance and exit.

.jpg)

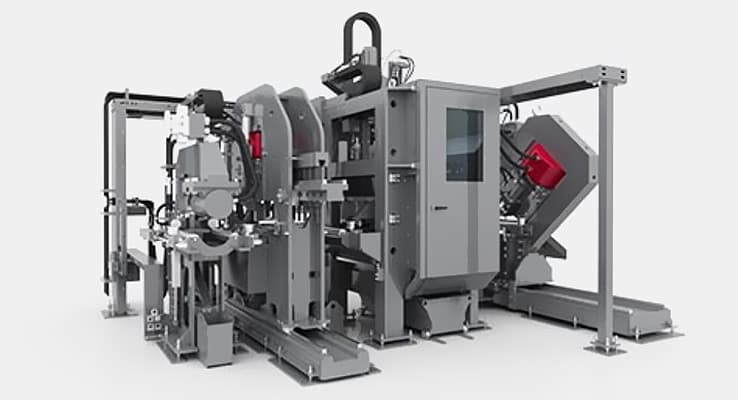

The Beam Layout Welding can be customized to fit the needs of civil and oil & gas construction. The Beam Layout Welding has component clamping as well as rotation via the headstock/tailstock. Beam Layout Welding uses a linear axis, X,Y and Z with laser seam tracking devices. The integrated control system with motor drives makes the machine fully automated.

Gulf States Saw & Machinery Co. have established themselves as the global leaders in steel fabrication technology. Beam Layout Welding machines allow steel fabricators to maintain a competitive edge in the industry and maximize tonnage.

Each section of conveyor has a maximum load capacity of 4,000 lbs. Conveyor speeds and welder input speeds are synced to reduce conveyor wear due to friction between the turning roll and the slower-moving beam near the welder entrance.

Gulf States Saw & Machinery Co. Beam-layout welding suppliers and manufacturers make different sizes. It will all depend on the requirements of the customer. It's best to fund an I-beam welding supplier and manufacturer. Not only will you receive the best prices, but you'll also be able help with installation.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.