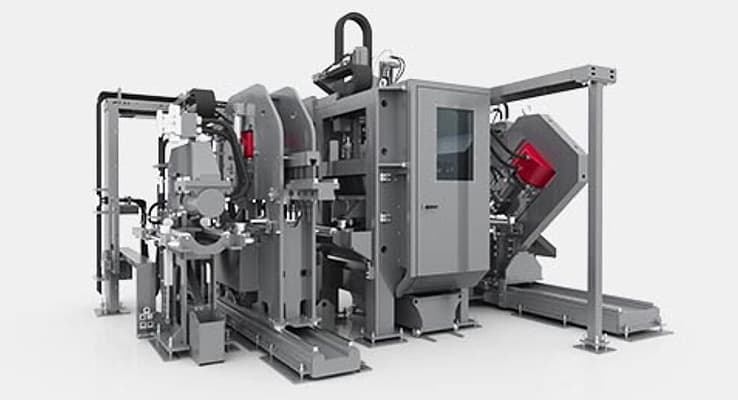

Beam Layout Welding Aluminum

A Conveyor System connects the Beam Layout Welding and Tacking Fixture to create a production line that allows for continuous beam production. The entrance and exit of Seam Welder and Tacking Fixture are controlled hydraulically by conveyors. Each station has its own controls that control the speed, direction, movement and movement of adjacent conveyors.