Brazing

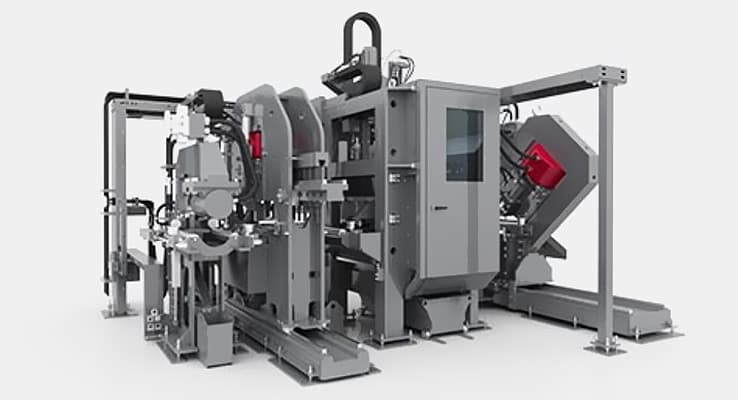

The TS72 tackup station provides hydraulic clamping and pre-fixtures of the leading edge for prefabricated beans. Franklin 40" Series CNC Gantry automates pick-and place loading of finished FLAGS from the Franklin CNC Flangeline System. Franklin "60 Series Gantries have a maximum length of 60 ft. and 75 ft. of travel storage.

.jpg)