Beam Layout Welding Research Paper

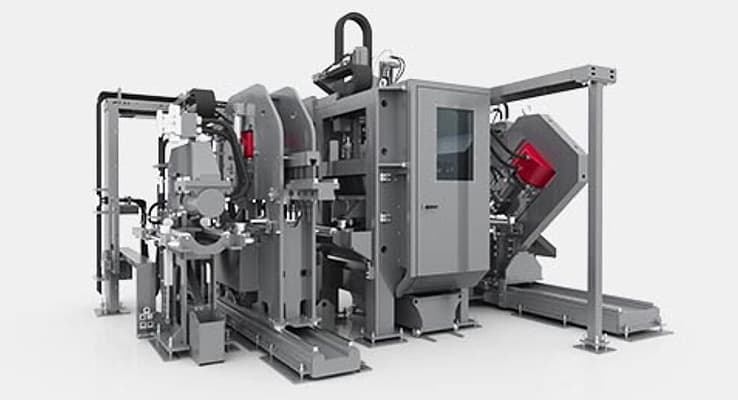

The WS-72 web-seamer station has a Lincoln Power Wave AC/DC welding machine and Max-Sa controls. Unique magnets pull web plates to the copper backing-up bar. Copper back-up bars are designed with a small flux groove that is fixed into an aluminum water-cooled bar.

.jpg)