How is AI beam made

An exclusive Beam Layout Welding head design can be provided for crane beam producers. Crane beams feature a "C-channel" top flange with short sides that face inwards toward the beam.

Most people believe that H beams and I beams are one and the same. They are not. They may share the same structure and function, but they are not the same thing. These are some differences to keep in mind.

Although they may look similar, if you really think about it, they are very different. Beam layout welding is usually heavier than I beams and more dense. This is because the beam layout welding can absorb and take in more force.

An exclusive Beam Layout Welding head design can be provided for crane beam producers. Crane beams feature a "C-channel" top flange with short sides that face inwards toward the beam.

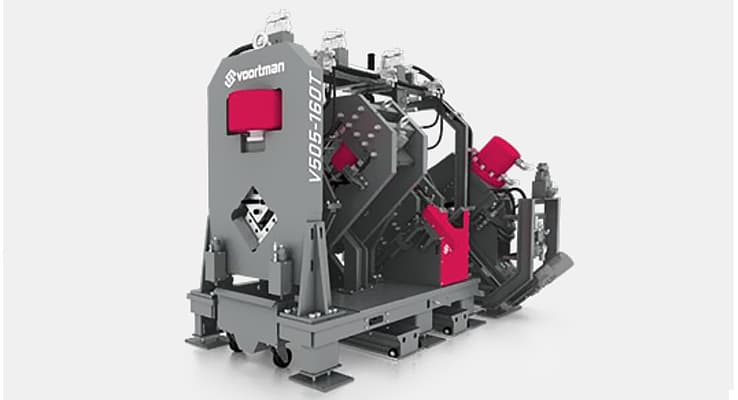

An Automated Structural Steel Beam Welding System enables structural steel fabricators to use a fully automated robotic welding system. It's compact, has complete robotic automation and integrates with the appropriate software. All sizes can now use robotic welding to solve welding production problems.

Do you still think that an H beam is the exact same thing as an I beam? You will find out more below. A single piece of plywood is all you need to see the importance of I beams. Place the plywood in a place where both its longitudinal ends can be supported only at the edge.

Traditional fitting requires a trained fitter to read and comprehend the assembly drawing, draw the measurement tape, and mark it. A laser projector system projects complete and detailed information directly onto the beam. With limited training, an operator can align the connection with projected lines and tack-weld where necessary.

Traditional fitting requires an experienced fitter who can read and understand the assembly drawings, use the measuring tape and mark where the beam is. A laser projection system can project all information directly onto a beam, so an operator, who has limited training, can align and tack weld the connection with that line.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.