What are the types of structural connection

The actual production capacity of a steel beam will depend on its size and type, but the typical output is about 2,000 tons per month. This can be achieved in an eight-hour shift by three operators.

Most people think H beams, and I beams, are the same. They are not. They might have the same purpose and structure, but they are different things! Here are some differences you need to be aware of:

The solid bed beneath the plate holds the metal plates while the weld head passes through it. This is where the H beam's flanges are made and cut. The web is then made from a length of plate. The web is then loaded onto a conveyor belt, similar to a welding roller, along with the flanges.

The actual production capacity of a steel beam will depend on its size and type, but the typical output is about 2,000 tons per month. This can be achieved in an eight-hour shift by three operators.

Think again if you believed that an I beam was the same as an h beam. It's all explained below. For a better understanding of the importance and benefits of I beams imagine a single plywood piece. Place the plywood just beyond the edge, so its longitudinal ends don't touch.

D3Touch from welding alloys is a touchscreen-based control technology that automates fully automated welding techniques. Welding Alloys incorporates new technology in all Welding Alloys equipment, improving the performance and accuracy of the weld process. This technology compliments our precision engineering mechanics and results in maximum performance.

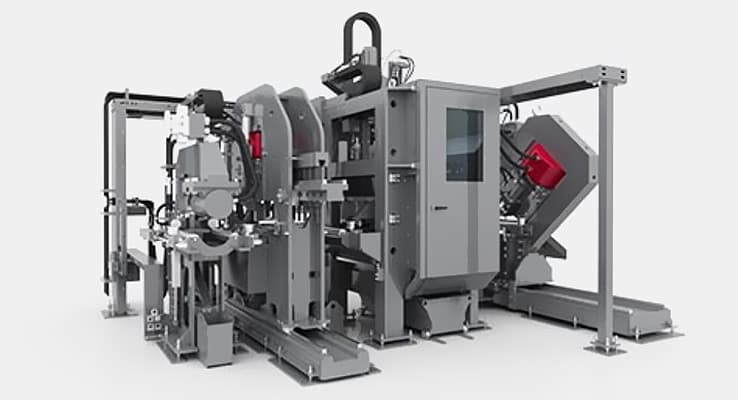

An Automated Structural Steel Beam Welding System can be described as a robotic welding machine that is specifically designed for structural steel fabricators. It offers a compact footprint, complete robotic automation, and integration with specialized software. The robotic welding solution can be applied to any size fabrication shop.

Gulf States Saw & Machinery Co. are world leaders in the field of structural steel fabrication technology. Beam Layout Welding machines give steel fabricators an advantage in the steel sector and allow them to maximize tonnage capacity.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.