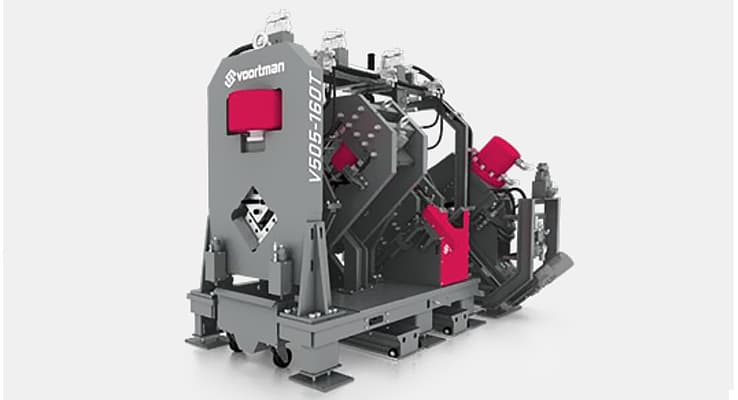

Beam Layout Welding Inc

The Beam Layout Welding, an automated welding machine, is completely customizable. It can join heavy duty structural steel box sections. This makes it ideal for civil construction as well as the oil & gaz and civil construction industries. The Beam Layout Welding machine has component clamping and rotation via both the tailstock or headstock. Beam Layout Welding operates in the linear direction X,Y,Z and laser seam track devices. The machine also has a wire feed system. The integrated control system, motor drives and wire feed system fully automates the machine.

.jpg)