Beam Layout Welding Class

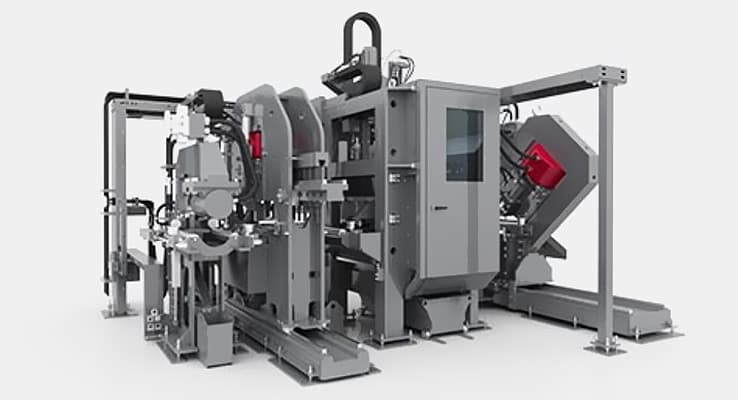

Beam Layout Welding comprises a beam, a horizontal column, an upper platform and a tool carriage mechanism. It also includes seam tracking, wire feeding, wire reel supporter as well as sAW welding power.

.jpg)

Beam Layout Welding enables you to join web sections by welding a 100% seam. You can also make long webs using short sections. The pieces to be joined will be aligned with an edge guide. They will then be clamped in place using air cylinders. The joint is sealed by the copper back-up plate. The welding head moves along a joint and welds it with a single-wire submerged arc.

The Beam Layout Welding has an electrical control panel that allows maximum system flexibility. You can choose to operate the welder in manual mode or automatic mode. Individual controls located on the control panel can be used to determine the sequence of operations. Also, each controller has its own welding parameters.

Beam Layout Welding comprises a beam, a horizontal column, an upper platform and a tool carriage mechanism. It also includes seam tracking, wire feeding, wire reel supporter as well as sAW welding power.

.jpg)

Beam layout welding can't be done manually. A H beam fabrication line/machine can handle multiple H beams simultaneously. It's a flat-laid machine, where long uncut plate are fed. The machine also handles the welding process of each plate to achieve the design requested.

This platform includes rail guards, stairs and a platform. This platform is for flux and wire storage. The operator can load flux hoppers onto the platform and then change wire drums and reels from the platform. Add auxiliary equipment to your Beam Layout Welding machine like the PHI's Beam Turning Device or Flange Titling Device. This will increase speed, agility, and productivity.

Beam Layout Welding can be downloaded remotely from any connected PC or network. It includes a one day data logger to record the machine's operations. This option allows for beams of maximum size 84" rather than the standard 72". All elements are modified to accommodate larger web size.

Gulf States Saw & Machine Co., Inc. has been providing professional fabrication equipment to professional fabricators since 1992. The nerve center of our operations is in Hueytown, Alabama, where we can serve our ten-state region effortlessly. Gulf States Saw & Machine Co., Inc. is the sister company to Alabama Tool & Supply Co., Inc. which was founded in 1979. We are a family owned and operated business.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.